Welcome to Shandong Baixinxin Metal Products Co., Ltd.

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Tel : +86 15954170725 E-mail : bxx@bxxsteel.com

ONLINE MESSAGE

420 Stainless Steel Plate

Stainless steel 420 Plate is a hardenable, martensitic stainless steel that is a modification of 410 stainless steel plate.

Category :

Stainless Steel Sheet

Key words :

420 Stainless Steel Plate

Details description

Product Introduction

ASTM A240 Type 420 contains increased carbon to improve mechanical properties. Typical applications include surgical instruments. SS 420 Plate is a hardenable, martensitic stainless steel that is a modification of SS 410 Plate.

Similar to SS 410 Plate, it contains a minimum of 12% chromium, just sufficient enough to give corrosion resistant properties. Available in different variations of carbon content 420 stainless steel plate is suitable for heat treatment. Stainless Steel 420 Plate has a 13% chromium content which gives the specification a level of corrosion resistance properties. British standard grades available are 420S29, 420S37, 420S45 Plate.

ASTM A240 Type 420 Applications:

Alloy 420 is used for a variety of applications where good corrosion and outstanding hardness is necessary. It is not suitable where temperatures exceeding 800°F (427°C) due to quick hardening and loss of corrosion resistance.

-

Needle valves

-

Cuttery

-

Knife blades

-

Surgical instruments

-

Shear blades

-

Scissors

-

Hand tools

Technical Data

Chemical Composition (%)

|

C |

Mn |

Si |

P |

S |

Cr |

|

0.15 |

1.00 |

1.00 |

0.04 |

0.03 |

12.0-14.0 |

Mechanical Properties

|

Tempering Temperature (°C) |

Tensile Strength (MPa) |

Yield Strength |

Elongation |

Hardness Brinell |

|

Annealed * |

655 |

345 |

25 |

241 max |

|

399°F (204°C) |

1600 |

1360 |

12 |

444 |

|

600°F (316°C) |

1580 |

1365 |

14 |

444 |

|

800°F (427°C) |

1620 |

1420 |

10 |

461 |

|

1000°F (538°C) |

1305 |

1095 |

15 |

375 |

|

1099°F (593°C) |

1035 |

810 |

18 |

302 |

|

1202°F (650°C) |

895 |

680 |

20 |

262 |

|

* Annealed tensile properties are typical for Condition A of ASTM A276; annealed hardness is the specified maximum. |

||||

Physical Properties

|

Density |

Thermal Conductivity |

Electrical |

Modulus of |

Coefficient of |

Specific Heat |

|

7750 |

24.9at 212°F |

550 (nΩ.m) at 68°F |

200 GPa |

10.3 at 32 – 212°F |

460 at 32°F to 212°F |

Equivalent Grades

| USA/ Canada ASME-AISI | European | UNS Designation | Japan/JIS |

|

AISI 420 |

DIN 2.4660 |

UNS S42000 |

SUS 420 |

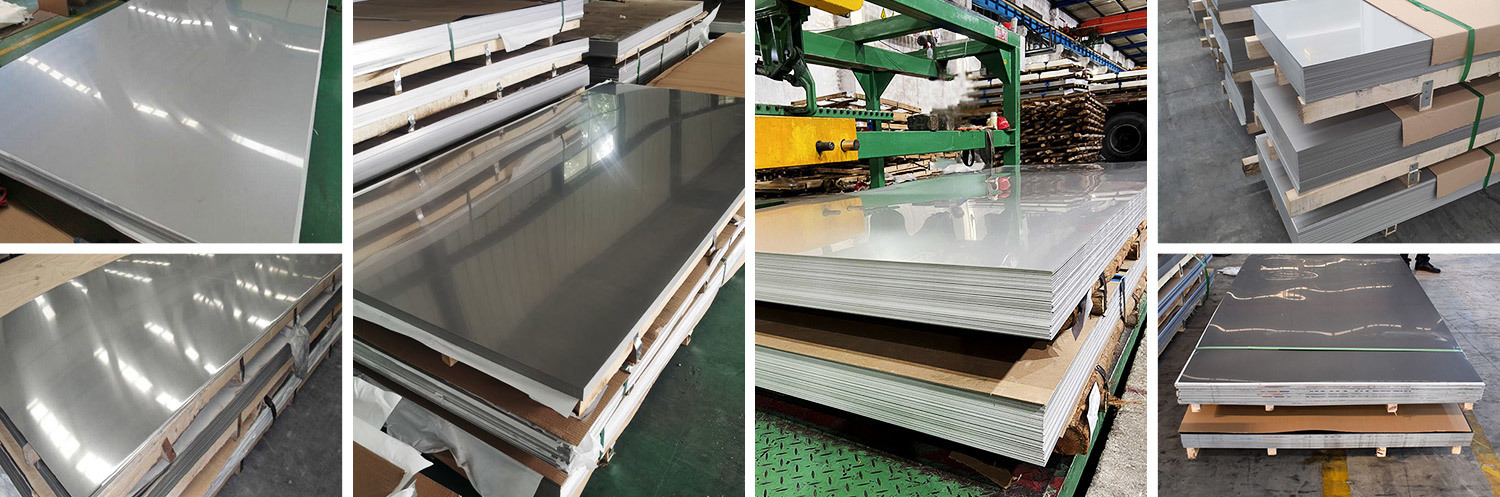

Product Details

Application

Factory

Packaging & Delivery

Certificate

FAQ

Q1:Can you send samples?

A:Of course, we can provide customers with free samples and express shipping service to all over of the world.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q5:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

ONLINE MESSAGE

RELATED PRODUCTS

409 stainless steel is a Ferritic steel that offers good mechanical properties and high-temperature corrosion resistance. It is commonly considered as a chromium stainless steel, with applications in exhaust systems of automobiles and applications that demand weldability.

201 Stainless steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304.

We are well-known providers of superior quality SS Strip, which are highly demanded in the market. Stainless Steel Strip 301 1/2 Hard 1/4 hard and full hard available. These types of stainless steel Strip are various size and shapes. Stainless Steel 301 in hot rolled and cold rolled available..

321 stainless is a titanium stabilized grade commonly used for service in the 1000-1600°F temperature range. For service temperatures up to about 1600°F, a stabilizing treatment at 1550-1650°F, air cool, may be used to provide optimum resistance to intergranular corrosion and to polythionic acid stress corrosion cracking.